GEW knows that great communication is the key to quality, efficient manufacturing processes. Through personal attention to each stage of the manufacturing process, we can cut expenses, reduce lead times, avoid costly errors and adapt designs to produce more efficient results for you.

From your initial appointment with us, we will advise, guide and facilitate effective communication with you, using our years of experience and industry knowledge to produce your project to the highest standards. Each project starts at design stage, which is carefully checked, reviewed and approved by you and our project managers to ensure a solid base for the following manufacturing processes.

We will continue to review, discuss and refine your designs at every stage of manufacture, offering prototype models, samples and pre-production tests to ensure your exact requirements are met and your satisfaction is thoroughly guaranteed.

We have design department at our location of manufacturing unit. Which works in close association with the engineering department of customers for critical dimensional requirements and complex product parameters. They prepare a shop floor/production drawings which are sent to customer for final approval prior to Fabrication process.

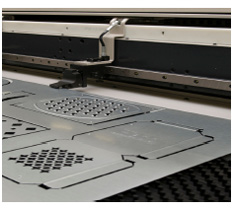

Advance software tools are used to create 3D model of product as required by the customer. These are then unfolded with software to get developed drawings of flat product. These drawings are then processing through programs of CNC Laser machines and CNC Bending machines.

We use software tools like Autocad, Solidworks and Nesting for Laser Cutting and Bending operations. Usage of these software tools enable us to cut and shape precision components with minimal wastage's and faster speed.